The shortage of heart donors, the need to develop new approaches to regenerate a failing heart is urgent

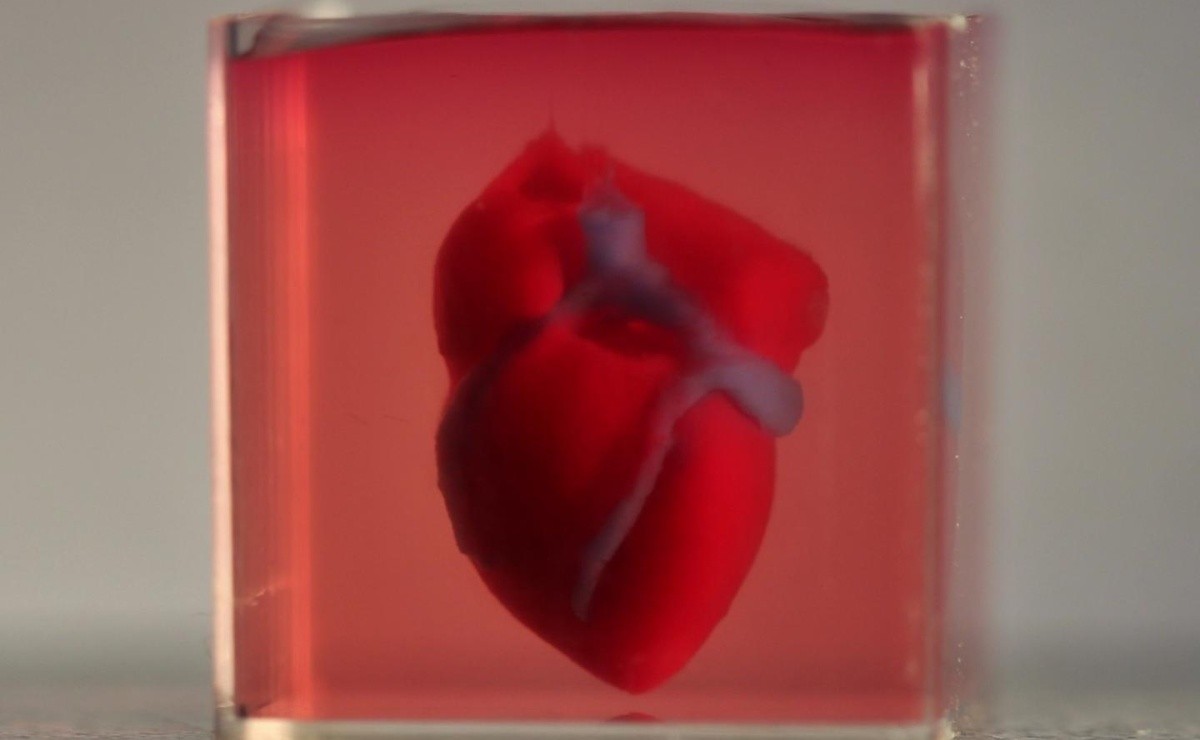

Tel Aviv University scientists print first functional 3D heart using cells and materials from a patient. The heart, produced in a laboratory and raised to cultivate more.

The 3D heart fully conforms to the biological characteristics of the patient’s heart. It took about three hours to print the entire heart.

Creating a model of the human heart is an important medical advance, yet this vascularized heart is about 100 times smaller than a human heart .

Similar in size to a rabbit’s heart, the new heart demonstrated the potential of 3D printing technology for the production of customized tissues and organs.

"This is the first time that a complete heart with cells, blood vessels, ventricles and chambers has been successfully made," said Tal Dvir, a professor at Tel Aviv University.

Heart disease is killing human beings around the world. Currently, heart transplantation is the only treatment available for patients with end-stage heart failure.

Given the great shortage of heart donors, the need to develop new approaches to regenerate a failing heart is urgent. But it seems that hearts made through 3D printing could be the solution.

The study research was conducted jointly by Dvir; Assaf Shapira from the Faculty of Biological Sciences at Tel Aviv University; and Nadav Moor, a doctoral student in Dvir’s lab.

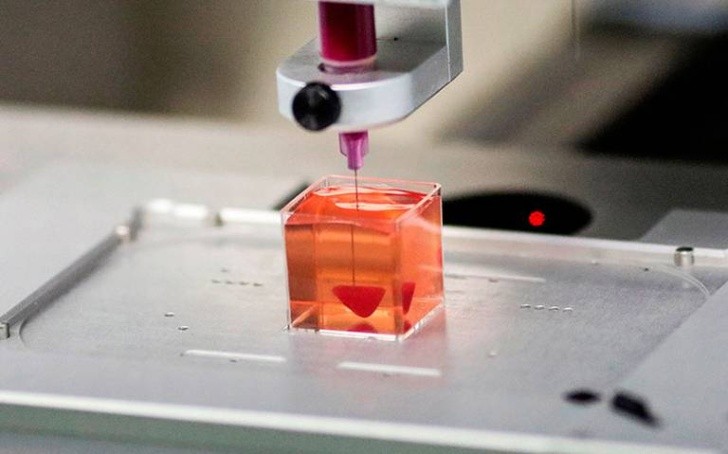

Shapira, who runs the lab, said "we take a biopsy of the patient’s adipose tissue and divide it into its components: cells and an extracellular matrix."

"As the extracellular matrix is processed into a gel, the cells are genetically modified to become stem cells, and then differentiate into heart muscle cells and cells that form blood vessels."

After this, the researchers mixed the cells with the gel to create "biological inks" that were loaded into the 3D printer. The printer is also loaded with axial tomography or magnetic resonance imaging of the patient.

The images generate high resolution shapes of the heart with patches that are adjusted to the anatomical and biochemical characteristics of the patient, reducing the possibility of rejection or malfunction in future transplants.

Now research is focused on studying the behavior and functionality of patches and printed hearts under controlled conditions in the laboratory and in transplants in animal models.

The artificial heart is expected to reduce the risk of rejection compared to transplanting a real heart from one human to another, a primary reason for treatment failure.

"Ideally, the biological material should possess the same biochemical, mechanical and topographic properties as the patient’s tissues," said Dvir.

Now the researchers are planning to grow the printed hearts in the lab to "teach them to behave" like hearts. The next step in his research will be to transplant 3D hearts into animals.

Also, the heart does not have the ability to pump. Currently cells contract, but they do not work together. There are many challenges ahead before transplanting the first human-made heart.

One of the main challenges is to make a mature heart, the size of a human heart and fully functional, and this requires the creation of billions of cells and not the millions of cells in the small model that the university produced.

After scientists produce a pumping heart, it will first be tested in animals before going the long way of regulating this cutting-edge process.

Perhaps ten years from now there will be organ printers in the world’s best hospitals and these procedures will be performed routinely, the Tel Aviv University statement said.